DOWNLOADS

Steel Belt for Wood Based Panel- Belt Application:Wood Based Panel Industry

- Type of Press:Continuous Mende Press

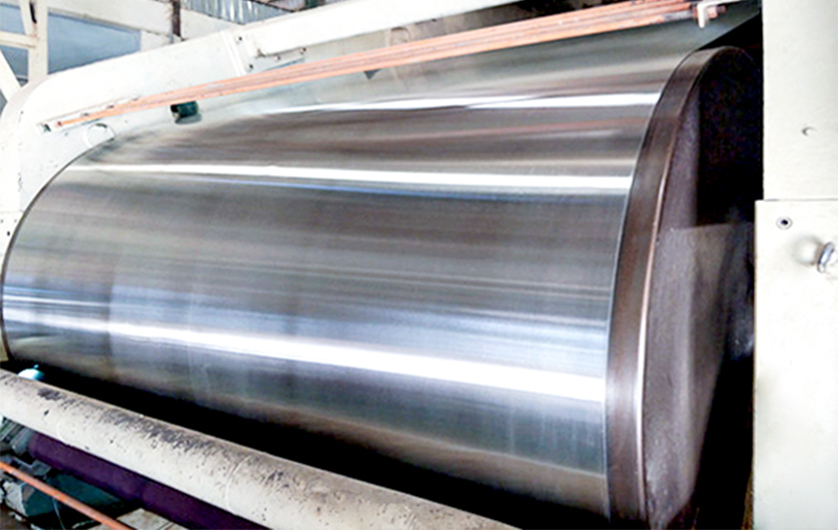

- Steel Belt:MT1650/MT1500

- Steel Type:Stainless Steel

- Tensile Strength:1600 Mpa

- Fatigue Strength:±630 N/mm2

- Hardness:480 HV5

STEEL BELT FOR MENDE PRESS | WOOD BASED PANEL INDUSTRY

Steel belt for Mende press bears extremely highstresses, because the belts bears continuous bending stress and thermal stress.The steel belt is bended 4 times and heated for each running cycle. The steel belt must be highly tensioned to exert high pressure onto mat & panel.

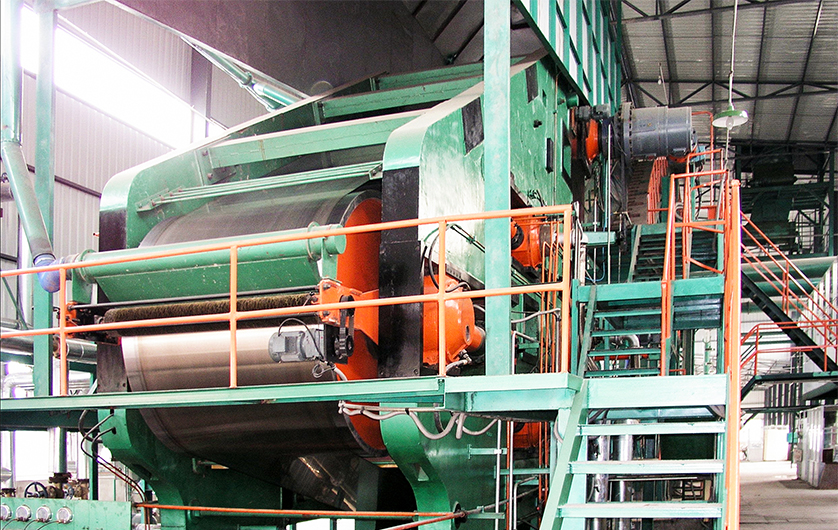

Compared with the double belt press, Mende press is an old type of press. It uses a stainless steel belt with thickness of 1.8 ~ 2.0mm. Its working principle is similar to that of a rubber drum vulcanizer (Rotocure). During the operation of the equipment, the steel belt is constantly folded back and forth at high speed. Such bending procedure requires extremely high strength (tensile, yield, fatigue) of the steel belt. In China, Mingke MT1650 steel belts are running on most of the Mende press lines.

Mingke Steel Belts can be applied to wood based panel (WBP) industry for continuous presses to produce Medium Density Fiberboard (MDF), High Density Fiberboard (HDF), Particle Board (PB), Chipboard, Oriented Structural Board (OSB), Laminated Veneer Lumber (LVL), etc.

Applicable Steel Belts:

| Model | Type of belt | Type of press |

| ● MT1650● MT1500 | Martensitic Stainless Steel Belt | Double belt pressMende press |

| ● CT1300 | Hardened and tempered carbon steel | Single opening press |

| ● DT1320 | Dual phase carbon steel (alternative to CT1300) | Single opening press |

Supply Scope of the Belts:

| Model | Length | Width | Thickness |

| ● MT1650● MT1500 | ≤150 m/pc | 1400~3100 mm | 2.3 / 2.7 / 3.0 / 3.5mm |

| ● CT1300 | 1.2 / 1.4 / 1.5 mm | ||

| ● DT1320 | 1.2 / 1.4 / 1.5 mm |

In wood based panel industry, there are three types of continuous presses:

● Double Belt Press, mainly produce MDF/HDF/PB/OSB/LVL/…

● Mende Press (which is also known as Calender), mainly produce thin MDF.

● Single Opening Press, mainly produce PB/OSB.