DOWNLOADS

Steel Belt for Wood Based Panel- Belt Application:Wood Based Panel Industry

- Type of Press:Continuous Double Belt Press

- Steel Belt:MT1650

- Steel Type:Stainless Steel

- Tensile Strength:1600 Mpa

- Fatigue Strength:±630 N/mm2

- Hardness:480 HV5

STEEL BELT FOR DOUBLE BELT PRESS | WOOD BASED PANEL INDUSTRY

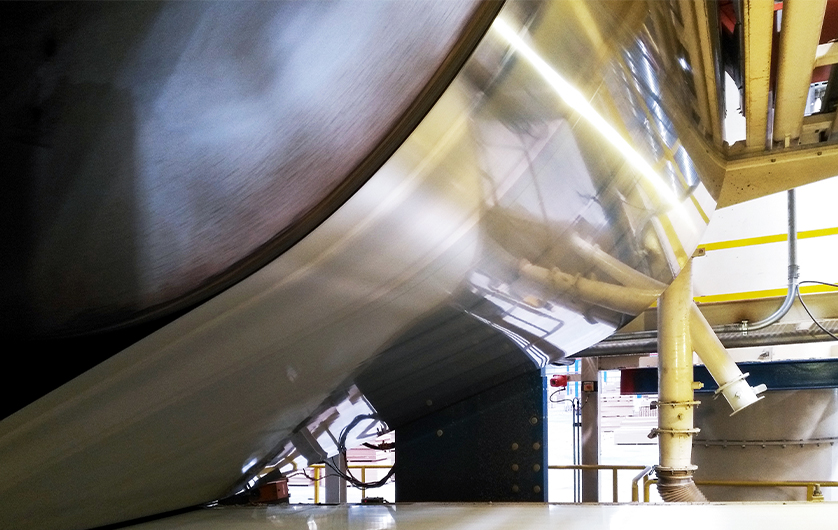

Wood based panel flat pressing production line adopts double belt press system, which works by upper and lower steel belts’continuous operation. Steel belt for wood-based-panel industry has high tensile/ fatigue strengths, hardness and good surface roughness and thermal conductivity, and the thickness variation, straightness and flatness are all excellent.

The continuous double belt press consists of upper & lower 2 pieces of steel belts, which is the latest wood-based panel press system, and major press manufacturers around the world are still constantly optimizing and upgrading this press.

The thickness of double belt press steel belt generally has 4 sizes of 2.3 / 2.7 / 3.0 / 3.5mm, which has high cost. The life time of steel belt is about 5-15 years according to different thickness panels and different material boards.

Mingke provides MT1650 stainless steel belt for double belt press line,Which is High-strength steel belt ,and commonly used in wood-based panel industry.

Mingke Steel Belts can be applied to wood based panel (WBP) industry for continuous presses to produce Medium Density Fiberboard (MDF), High Density Fiberboard (HDF), Particle Board (PB), Chipboard, Oriented Structural Board (OSB), Laminated Veneer Lumber (LVL), etc.

Applicable Steel Belts:

|

Model |

Type of belt | Type of press |

| ● MT1650 | Martensitic Stainless Steel Belt | Double belt press, Mende press |

| ● MT1500 | Martensitic Stainless Steel Belt | Double belt press, Mende press |

| ● CT1300 | Hardened and tempered carbon steel | Single opening press |

| ● DT1320 | Dual phase carbon steel (alternative to CT1300) | Single opening press |

Supply Scope of the Belts:

|

Model |

Length | Width | Thickness |

| ● MT1650 | ≤150 m/pc | 1400~3100 mm | 2.3 / 2.7 / 3.0 / 3.5mm |

| ● MT1500 | 2.3 / 2.7 / 3.0 / 3.5mm | ||

| ● CT1300 | 1.2 / 1.4 / 1.5 mm | ||

| ● DT1320 | 1.2 / 1.4 / 1.5 mm |

In wood based panel industry, there are three types of continuous presses:

● Double Belt Press, mainly produce MDF/HDF/PB/OSB/LVL/…

● Mende Press (which is also known as Calender), mainly produce thin MDF.

● Single Opening Press, mainly produce PB/OSB.