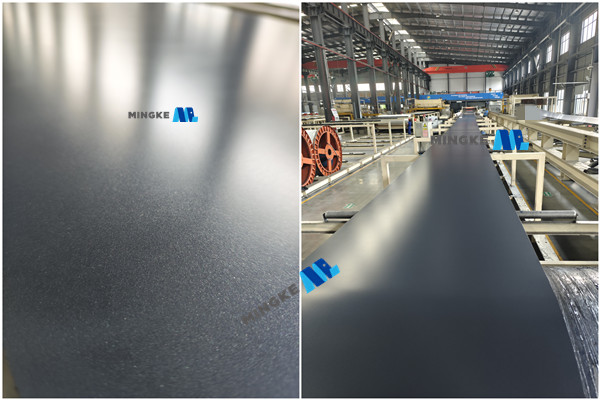

Mingke Teflon steel belt has been grandly unveiled!

This breakthrough product is not only the result of the wisdom of our R&D team, but also a powerful statement of the infinite possibilities of the future, marking a solid step forward on the global industrial stage.

Teflon coatings have the following features:

1. Non-sticky:

• Cooking: This is the most well-known property of Teflon coatings and is widely used in non-stick pans, baking trays, baking molds, continuous tunnel ovens, etc.The food does not adhere easily to the coated surface, which not only reduces the food sticking to the pan and burning, making the cooking process easier, but also facilitates the cleaning work after the meal.

• Industrial applications: The use of Teflon coating on the surface of industrial molds and mechanical parts can prevent the adhesion of processed materials, reduce production interruptions and equipment maintenance frequency due to material adhesion, and improve production efficiency. For example, spraying Teflon coating on the molding mold of rubber, plastic and other products can make the product release smoothly.

2. High temperature resistance: Teflon material itself can withstand high temperatures, and can withstand high temperatures to 300°C for a short time, and can be used continuously between 240°C – 260°C. Therefore, it can be used to make appliances and equipment parts used in high-temperature environments such as furnace walls, stove plates, and heat sealing machines. In the aerospace sector, some parts that are exposed to high temperatures are also protected with Teflon coatings.

3. Abrasion resistance: Teflon coating has high surface hardness and good wear resistance under high load operation. This feature allows it to extend the service life of the coated object and reduce wear and damage due to friction. For example, spraying Teflon coating on the inner wall of bearings, gears, and automobile machinery parts in the machinery industry can improve the wear resistance of parts and reduce the maintenance cost of equipment.

4. Corrosion resistance: Teflon coating is less affected by the chemical environment, can withstand the action of most organic solvents, is almost insoluble in all solvents, and also has strong corrosion resistance to acids, alkalis, salts and other chemicals. Therefore, it is often used to coat the inner walls of chemical equipment, pipes and vessels to protect equipment from chemical corrosion.

5. Moisture resistance: The surface of the coating is hydrophobic and oleophobic, which is not easy to get water and oil, and it is not easy to get solution during production and operation. Even if there is a small amount of dirt adhered, it can be removed by a simple wipe, which is easy to clean, saving production time and maintenance costs.

6. Electrical insulation: Teflon coating is often used for surface coating of electronic components, cables and circuit boards, etc., to provide good electrical insulation protection and ensure the normal operation and safety of electronic equipment.

7. Food safety: Teflon coating meets relevant food safety standards and can come into contact with food. Therefore, it is widely accepted in the field of food processing and cooking, and is used to coat parts that come into direct contact with food, such as food processing equipment and packaging machinery.

…………

These characteristics make Teflon steel belts widely used in many industries such as automation equipment, conveyor systems, high-temperature environments, chemical treatment and food processing.

Welcome to inquire~~

Post time: Oct-25-2024