MT1650

DOWNLOADS

MT1650 Stainless Steel Belt- Model:MT1650

- Steel Type:Stainless Steel

- Tensile Strength:1600 Mpa

- Fatigue Strength:±630 Mpa

- Hardness:480 HV5

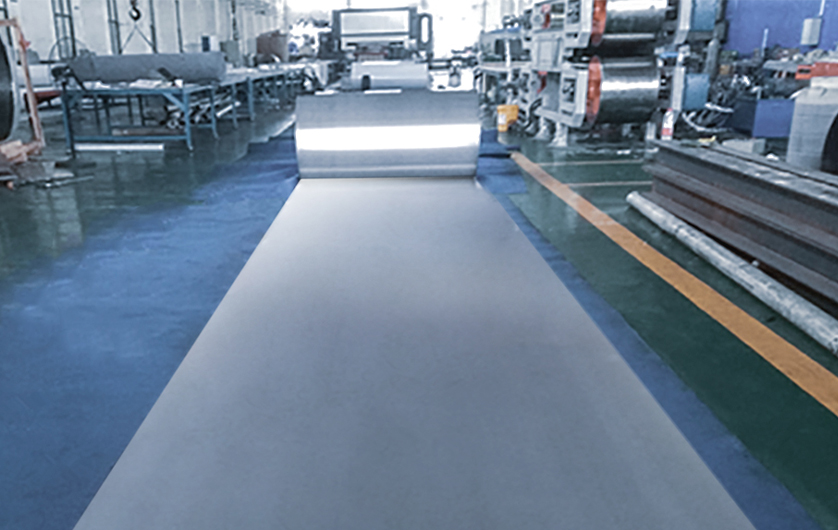

MT1650 MARTENSITIC STAINLESS STEEL BELT

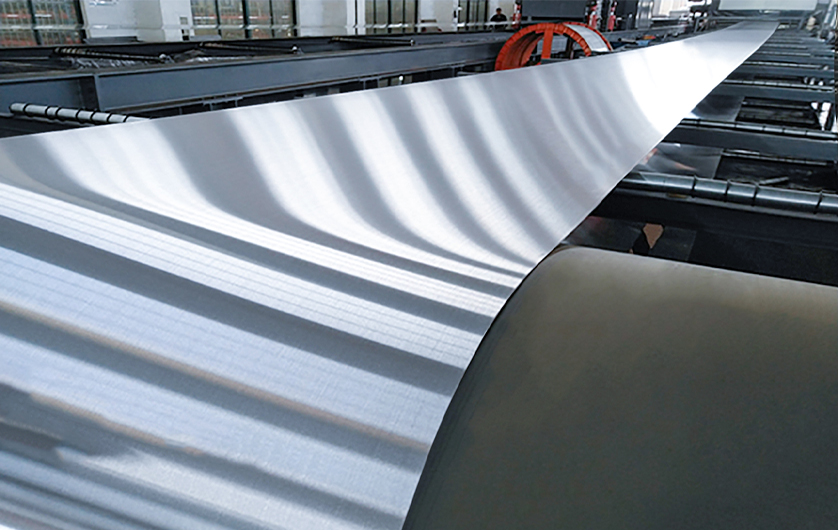

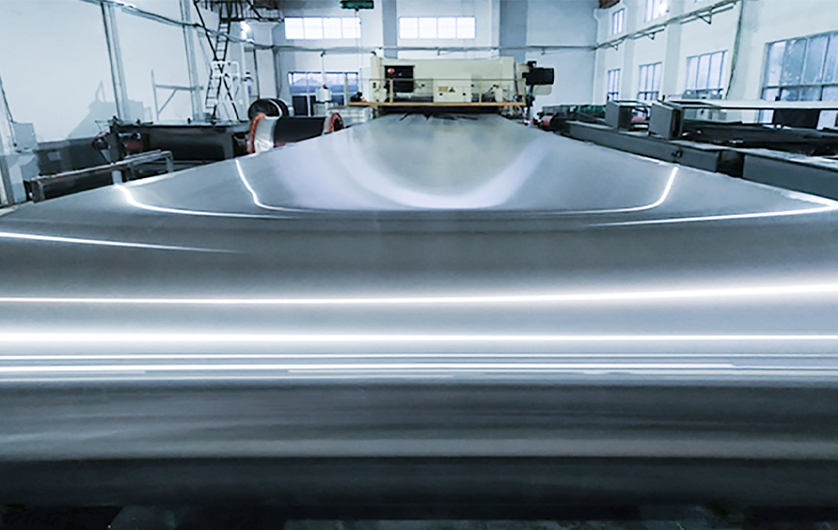

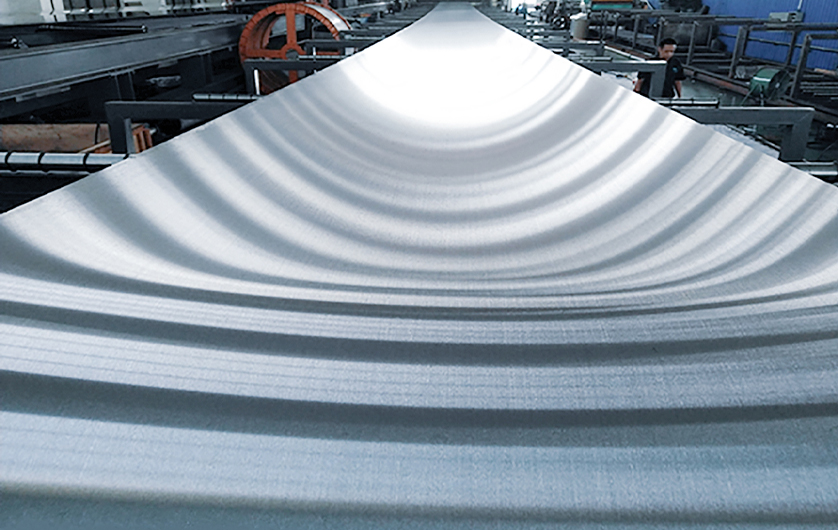

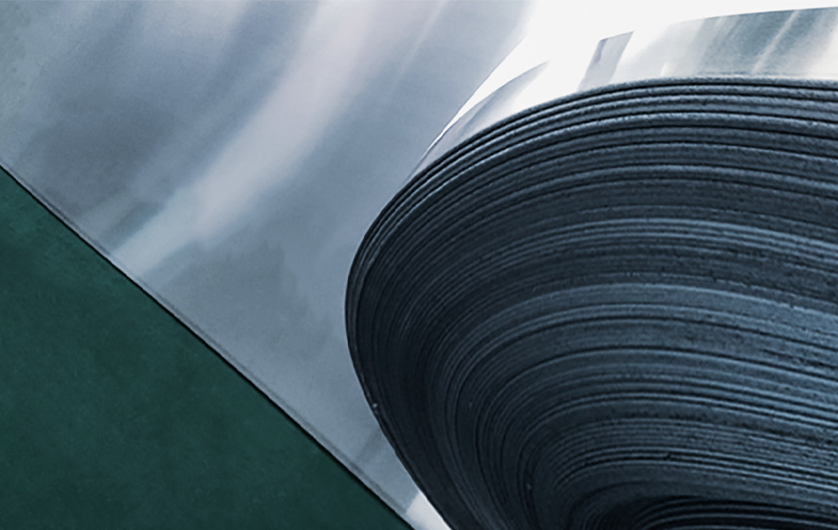

MT1650 is a low carbon precipitation-hardening martensitic stainless steel belt, which can be heat treated to improve strength & hardness. It can be further processed to supper-mirror-polished belt and textured belt. MT1650 steel belt is very suitable high-strength steel belt for wood-based-panel continuous double belt press line, Mende press line and rubber drum vulcanizer (Rotocure) on the global market.

Applications

● Wood based panel

● Rubber

● Ceramic

● Automotive

● Papermaking

● Sintering

● Lamination

● Others

Scope of supply

● Length – customize available

● Width – 200 ~ 9000 mm

● Thickness – 1.0 / 1.2 / 1.6 / 1.8 / 2.0 / 2.3 / 2.7 / 3.0 / 3.5 mm

Tips: Max. width of a single belt is 1550mm, customized sizes via cutting or longitudinal welding are available.

Compared with MT1500, MT1650 has better tensile strength, yield strength and fatigue strength. It has been used in wood-based panel industry and rubber industry. The wood based panel industry is mainly used in the flat pressing production line and the roll-pressing line, and the rubber industry is mainly used in rubber drum vulcanizer (Rotocure). Wood based panel flat pressing production line adopts double belt press system, which works by upper and lower steel belts’ continuous operation, and it is has high requirements for steel belt surface roughness, thermal conductivity, thickness variation, straightness and flatness. The wood-based panel roll-former line adopts the Mende press, Steel belt for Mende press bears extremely high stresses, therefore, the fatigue strength of the steel belt is required to be higher. Even though both steel belt model can be used in wood based panel industry, However, considering that customers produce different plates, contact Mingke, and we will recommend more suitable steel belt model for customers.

Since we established, Mingke has empowered wood based panel industry, chemical industry, food industry, the rubber industry, and film casting etc. Apart from steel belt, Mingke can also supply steel belt equipment, such as Isobaric Double Belt Press, chemical flaker / pastillator, Conveyor, and different steel belt tracking system for different scenarios.

Product Display